Pioneering New Cotton Project concludes: Sharing eight recommendations for making circular fashion a reality

Back to overviewWritten by Brooke Roberts-Islam, writer, author, consultant and Founder of TECHSTYLER

The New Cotton Project has come to a close, marking the end of the ‘world-first’ fashion industry project where twelve pioneering organisations joined forces to demonstrate a circular textile-to-textile model for commercial garment production in Europe. In truth, the consortium’s remit extended beyond this ‘on paper’ deliverable though, since the wider context was looming EU legislation in the Circular Economy Action Plan (CEAP) and Textiles Strategy, including extended producer responsibility (EPR) and ecodesign for sustainable products (ESPR).

As part of EPR, European Union (EU) countries must implement (by 1st January, 2025) separate collection of textiles for re-use and recycling. The infrastructure for this decentralised textile collection does not yet exist, nor has adequate data been gathered on the likely composition and volumes of these textiles. Therefore, the outcome of the New Cotton Project was not simply to define a blueprint for how textiles could be collected, sorted, recycled and remade into new garments–it was a baseline for understanding the necessary supply chain terms and relationships conducive to overhauling a linear business model that has, to date, been concerned simply with the value rather than volume, with little regard for when textiles become ‘waste’.

The era of industry abandon over textile waste is all but over, since EPR fees will subject brands to a ‘waste tax’; but furthermore, the New Cotton Project illustrated that discarded clothing is a valuable resource with multiple avenues for increasing utility and value generation, with design, materials choices and care methods being key levers for extracting more value from each product over a longer time frame before eventual recycling is required (once utility is exhausted, in contrast to today’s loss of such value to the depths of municipal landfill).

One of the garments by H&M Group produced within the project

In the final month of the New Cotton Project, the consortium hosted a roundtable with EU policymakers to discuss ‘Setting EPR up for success’ and to disseminate the project’s findings and recommendations. It transpired that ‘success’ depends on EPR policies supporting the necessary business models for sorting, pre-processing and recycling organisations. The two main challenges foreseen throughout the discussions were: establishing the logistics of European EPR schemes, and meeting the financing requirements of circular value chains.

The consortium also submitted a white paper (currently being peer- reviewed) on ‘Driving the Transition Toward Circular Textiles, along with an environmental LCA analysing the entire value chain (currently under peer review). The LCA would fill a critical data gap for evaluating the potential gains (in economic, social, and environmental terms) from implementation of a value chain for cellulose-rich textile-to-textile recycling and garment production in Europe. Critically, these findings would also provide timely data to better inform Ecodesign guidelines for textile products within ESPR, which have endured criticism for the use of data estimates and approximations.

Following the conclusion of the 3.5 year project, 8 key findings and recommendations were published to help guide the next steps for stakeholders:

THE WIDE SCALE ADOPTION OF CIRCULAR VALUE CHAINS IS CRITICAL TO SUCCESS

Textile circularity requires new forms of collaboration and open knowledge exchange among different actors in circular ecosystems, including actors beyond traditional supply chains and previously disconnected industries and sectors.

CIRCULARITY STARTS WITH THE DESIGN PROCESS

When creating new styles, it is important to keep an end-of-life scenario in mind right from the beginning. If designers make it as easy as possible for the recycling process, it has the bigger chance to actually be feedstock again.

BUILDING AND SCALING SORTING AND RECYCLING INFRASTRUCTURE IS CRITICAL

In order to scale up circular garment production, there is an urgent need for technological innovation and infrastructure development in end-of-use textiles collection, sorting, and the mechanical pre-processing of feedstock.

IMPROVING QUALITY AND AVAILABILITY OF DATA IS ESSENTIAL

There is still a significant lack of available data to support the shift towards a circular textiles industry. This is slowing down development of system level solutions and economic incentives for textile circulation.

THE NEED FOR CONTINUOUS RESEARCH AND DEVELOPMENT ACROSS THE ENTIRE VALUE CHAIN

The project demonstrated that the scaling of fibre-to-fibre recycling will continue to require ongoing research and development across the entire value chain, improving sorting systems is crucial and the manufacturing process will benefit from ongoing innovation in processing methods.

THINKING BEYOND LOWER IMPACT FIBRES

The New Cotton Project LCA analysis shows that even if we reduce the environmental impacts by using recycled fibres, there is still work to do in other life cycle stages.

CITIZEN ENGAGEMENT

An adidas quantitative consumer survey conducted during the project revealed that there is still confusion around circularity in textiles, which has highlighted the importance of effective citizen communication and engagement activities.

COHESIVE LEGISLATION

With several pieces of incoming legislation within the EU alone, the need for a cohesive and harmonised approach is essential to the successful implementation of policy within the textiles industry.

In addition to the 8 action areas, the consortium collated some highly nuanced unpublished conclusions that warrant airtime and offer some interesting contextual perspectives.

Reflecting on their experiences, the consortium members compiled suggested actions for each stakeholder group according to the role they will play in establishing the circular textile value chain in Europe. The list contains distinctly human-led lessons from the ‘day-to-day’ experience of trying to work with all the businesses and technologies needed to gather textile waste and eventually make new garments from it to sell in the EU market.

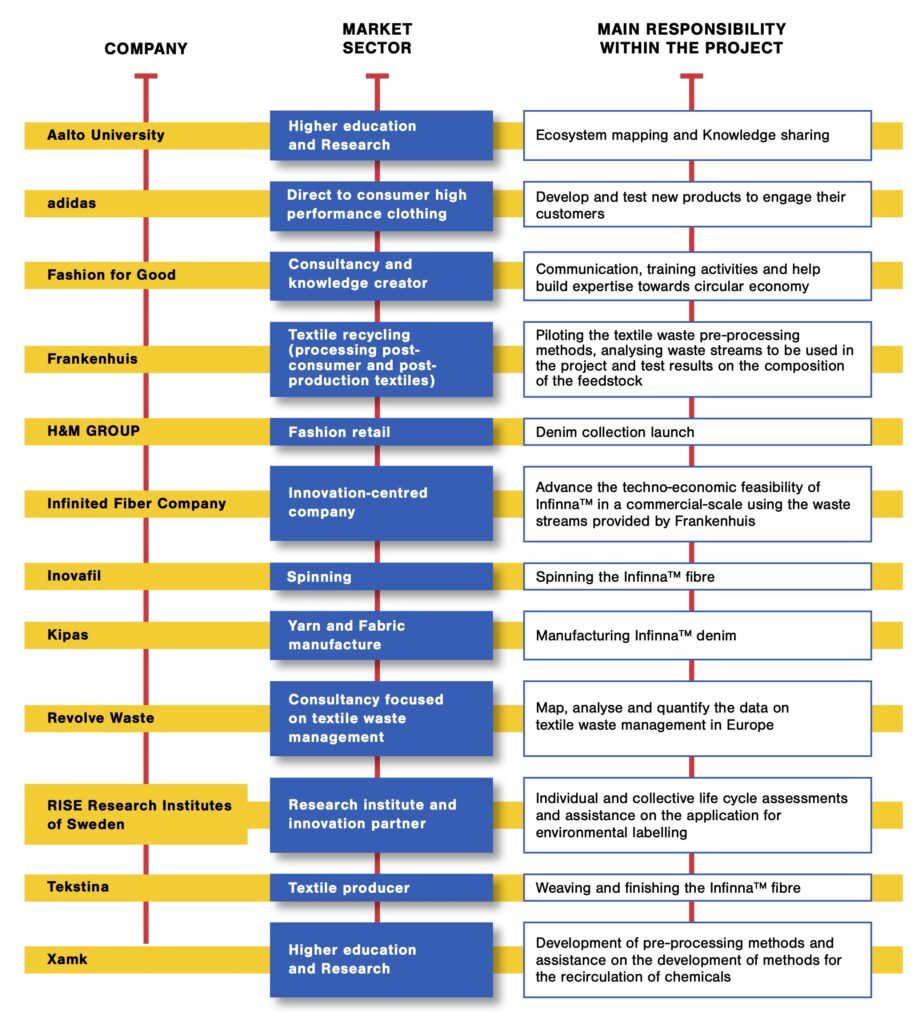

Before diving into the nuanced lessons, here is an overview of all the stakeholders involved in the New Cotton Project:

Consortium partners and their details (Circular Ecosystem’s Blueprint, Aalto University, 2022)

The consortium members distilled their lessons into advice according to these six stakeholder groups: collectors/sorters/pre-processors, recycling technologies, manufacturers, brands, research institutes, and national and EU policymakers. Here are some excerpts:

Recyclers are urged to help build circular textiles infrastructure by: ‘actively sharing first-hand information and [business and technical] insights; and joining conversations with regulators to ensure they act with sufficient understanding of the infrastructure specifications and requirements for efficient sorting, feedstock distribution and recycling processes’; a significant departure from business as usual. However, the consortium additionally proposes that: ‘recyclers could share a shortlist of the most challenging impurities, [which] would help designers and product developers to understand the consequences of including these impurities in new products’.

True, this is specific guidance for one (pivotal) stakeholder group, but it serves to demonstrate the degree to which establishing circular textiles infrastructure in Europe depends on recyclers (in this example) extending their work way beyond simply complying with regulations while operating commercial businesses. Their extended remit could be summarised this (in addition to textile recycling):

- Investing in emerging technologies

- Educating EU policymakers who aim to turn their Circular Economy Action Plan into a living, functioning industry and economy (but lack the industrial knowledge to devise policies that will enable and support it)

- Partnering with newly established (and possibly co-dependent) textile collection businesses

- Advising brands and designers on best practice for textile sourcing and design to maximise product value ‘in life’ and recyclability at end-of-life

These actions no doubt come under the banner of ‘pre-competitive collaboration’ so often mooted on stage at conferences and summits about circularity; but regardless of definition, the New Cotton Project’s lessons indicate that stakeholders should be willing to operate outside of today’s ‘business as usual’ scope and instead foster symbiotic relationships with policymakers, brands and other stakeholders, where they willingly share their business data and know-how (generally termed ‘trade secrets’). These conclusions point to ‘soft skills’ and ‘culture shifts’ that have not been discussed for textile-to-textile recycling and garment production before; consequently, much of the discussion about textile circularity has tended to lean on technical and economical feasibility, without acknowledging human resistance to change and stepping out of short-term business thinking and guarded competitiveness.

New Cotton Project installation at the “Designs for a Cooler Planet 2023: Invisible” exhibition by Aalto University. Photography: Jere J. Aalto

The willingness to share business data and consider another stakeholder’s business needs within another business’s strategic planning is a vast leap, and makes overcoming technical recycling limitations look like child’s play. Despite the magnitude of the challenge, it’s clear that without data sharing and symbiosis, co-dependent businesses in a circular value chain will be ill-informed, ill-equipped, and will probably break, reverting from circular to linear.

The consortium’s advice for brands centred on design and material procurement: ‘when creating new styles, keep end-of-life scenarios in mind from the beginning [to] dictate what embellishments, prints, [and] accessories can be used’. This sounds reasonable and pragmatic, however the reality of restricting designers (the team members usually afforded the greatest deference and freedom since their ideas result in products that drive revenue) is far less straightforward and absolute. Restricting designers to an approved list of materials re-frames their work as being primarily of practical and environmental concern, rather than ephemeral and aesthetic concern, and that will be an extremely challenging stance, especially for ‘luxury’ and SME brands, which account for the majority of brands in Europe.

Beyond suggesting reprioritization away from designer autonomy and instead toward utility and recyclability, another consideration is that the largest brands and retailers in Europe source their products from suppliers in Asia. Those suppliers often conduct much (or all) of the design, sourcing and product development on behalf of brands. This means that the relationship between brands and their suppliers would need to change drastically from today’s guarded ‘arms-length’ negotiations to more equitable relationships based on transparency. Such a shift would break down the barriers erected by European and North American brands in the 1950’s when they outsourced product to Asia, enabling brands to increase their negotiation power, reduce their costs and shifting production risks to their suppliers. Circularity and recyclability now appear to depend on that risk being shared in order to be mitigated, lest brands fall foul of upcoming EU regulations.

Conclusion

Yes, the project’s 8 key findings and recommendations set out a solid framework for circular textiles in Europe; but more importantly, the consortium member lessons demonstrate that the culture and terms of business conduct should change if those recommendations are expected to happen in practice. The willingness to share business information that was previously guarded, and consider the needs of parallel businesses beyond one’s own are likely as important as obtaining the required recycling technology to turn discarded clothes into new fibres.

The New Cotton Project may have concluded but the research and commercial partnerships it forged have not. Project consortium members Infinited Fiber Company, adidas and Aalto University are now involved in the EU-funded T-REX (Textile Recycling Excellence) Project, which aims to develop a harmonised blueprint for closed-loop sorting and recycling of household textile waste in the EU. ‘T-REX’ also aims to identify circular business opportunities for the EU textile sector.

The vast learnings from the New Cotton Project will remain available on the project website until 2026.